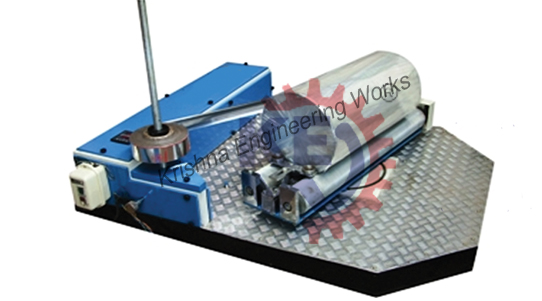

Roll Wrapping Machine

Krishna Engineering Works dealing on manufacturing and exporting Roll Wrapping Machine from India. A genuine specialized supplier of Roll Wrapping Machine. We are a leading manufacture, export and supplier of Roll Wrapping Machine. Our machines are designed with wide range of quality for long lasting heavy duty process, specially for cutting in different sizes from 12 mm to 1000 mm. We are a leading manufacturer, exporter and supplier of all types of Roll Wrapping , Stretch Wrapping , Carton, Water Tank , Cloth Roll , Nylon Roll, etc.

Different Types of Roll Wrapping Machine:

- Roll Wrapping

- Reel Wrapping

- Pallet Wrapping

- Mini Roll Wrapping

- Ring Wrapping

- Carton Box

- Coil Wrapping

- Stretch Film

- Door Wrapping

- Water Tank

Basic Standard Features:

- Highly economical and huge savings over shrink packing/gunny bundles

- Suitable for packing any rolls of Denim Cloth, Curtain Cloth, Carpets, Foam sheets, Upholsteries, Fabrics, Film, Paper etc.

- Occupies less space

- High productivity 30 – 50 rolls/hour

- Tremendous savings in labour, time and money

- Highly durable dust and moisture proof packing

- Powered Pre-Stretch unit to minimize film consumption

- Variable stretch percentage up to 300%

- Adjustable traverse to suit different roll width

- Controlled film tension

- Variable Overlap, Variable End Reinforcements, Variable Stretch Percentage and Variable Roller Speed

- Digital counters for end reinforcement wrap setting, film consumption and stretch percentage display

- Simple to operate, sturdy & safety control panel

- Cradle for easy loading of film

- Easy loading and unloading of Fabric roll and ease of integration into conveyor lines

- High energy saving-more than 90% saving over shrink wrapping

- Minimum service points

- Payback period is only few months

- Excellent after-sales-service support

- 12 months warranty

Details:

| Height (above GL) | 350 mm |

| Speed | 50 meters/minute |

| Maximum stretch | 300% |

| Installed power | 1.5 kW |

| Power supply | 220V, Single phase, 50Hz |

- Protection against moisture and dust

- Prevent telescoping of rolls

- Save packaging cost, Labour and time

- Better identifications of wrapped products

- Give stability to the product

- Economical way of packaging